-40%

Automotive Digital Tool Car Painting Thickness Gauge Coating Tester 2.2mm/86mil

$ 11.77

- Description

- Size Guide

Description

Shop CategoryStore Home

Automotive Tester

Digital Multimeter

Digital Clamp Meter

Voltage Tester

Environment Tester

Battery Tester

Metal Detector

Pen Probe Digital Multimeter

Stud Finder

Wood Moisture Tester

Handheld Digital Scopemeter

Professional Tester

Home Meter

Netcable Tester

Other

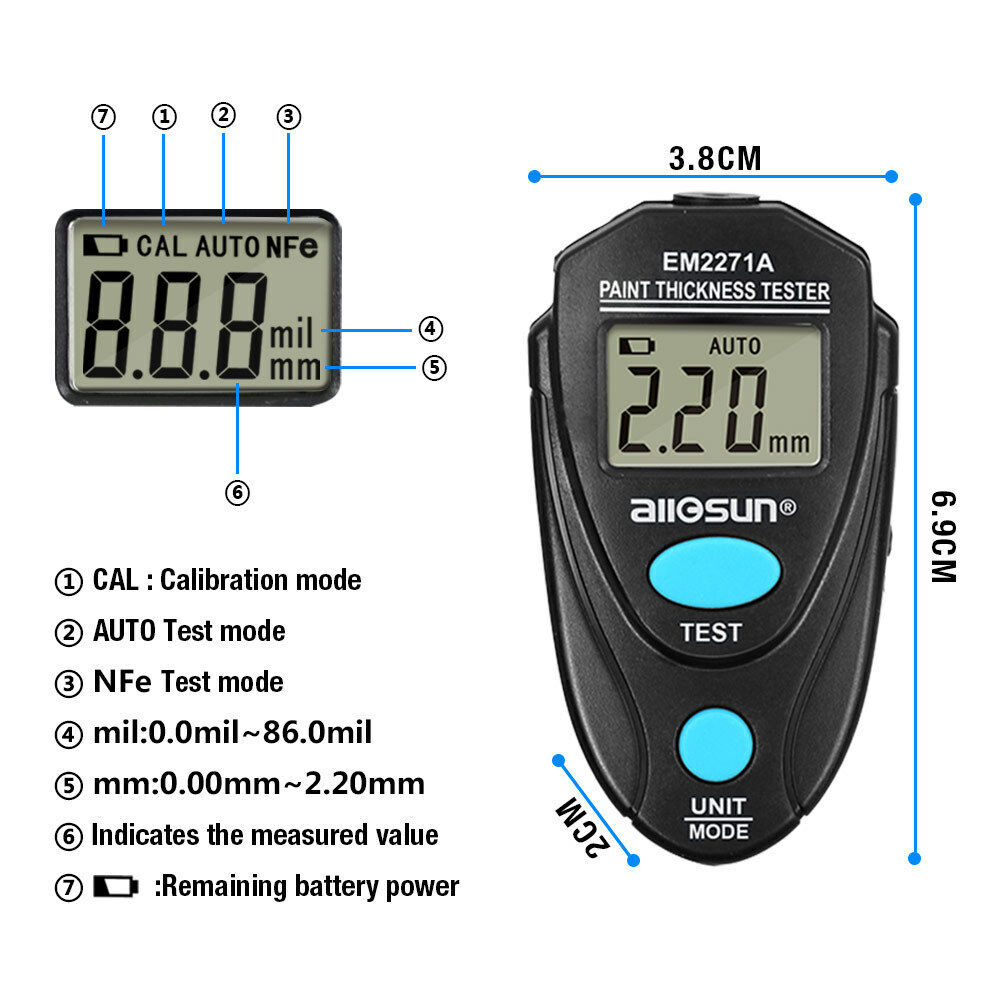

Automotive Digital Tool Car Painting Thickness Gauge Coating Tester 2.2mm/86mil

This tester is designed to not-destructively measure the thickness of non-magnetic coatings(including paint,enamel,plastic,epoxy,etc)on iron,steel or aluminum.

Notice:

In order to obey the shipping security rules and passing the customs security check. We had put a insulation strip under the battery to make it insulated. You need to take the strip off and re-install the battery for the first-use.

Specification

Type:

Painting Thickness Tester

Measuring Range:

0.00mm - 2.20mm, or 0.0mil - 86.0mil

Measurement Accuracy:

For measurements in “NFe” or “Fe” test mode in which the tester has been properly calibrated: ± 0.05mm

For measurements in auto test mode and on object with aluminum substrate: ± ( 2% of reading + 0.05mm )

For measurements in auto test mode and on object with steel substrate: ± ( 10% of reading + 0.10mm )

Note:The above accuracy specifications assume that the operating temperature is 23º C ± 5º C and the

operating relative humidity is ≤ 75%.

Resolution:

0.01mm/0.1mil

Power Supply:

3V button cell, CR2032 or equivalent, 1 piece

Operating Environment:

0°C~40°C, Relative humidity

Temperature Coefficient:

0.15x(2% of reading ± 0.05mm)/°C(28°C)

Storage Environment:

Temperature:

-10ºC to 50ºC

Relative Humidity:

≤ 80%

Size:

6.9*3.8*2cm

Weight:

About 29g(including button cell)

Operating Instruction

1. Hold the tester and make sure that it is as least 20cm away from the object to be tested and other objects.

Then press the "

TEST

" button to turn on the tester. The display shows all segments and symbols

momentarily. Then it shows the "

AUTO

"

symbol and the measurement unit “

mm

”, and meanwhile, "

",

" ", and "

" appear on the display sequentially and repeatedly.

2. Press the "

" button to select desired measurement unit - mm or mil.

3. After you turn on the tester, it will default to auto test mode and the display will show

"

AUTO

" as an

indication. You can repeatedly hold down the "

" button for about 1 sec to step through "

NFe

" test mode

( "

NFe

" appears as an indication ), "

Fe

" test mode ( "

Fe

" appears as an indication), and back to the auto

test mode ( "

AUTO

" appears as an indication ).

I

f you can not obtain the naked substrate of the object to be measured and have not calibrated the tester

using the naked substrate of this object, you must select auto test mode. The advantage of using auto test

mode is that it is not necessary to calibrate the tester, and the disadvantage is that measurement accuracy in

auto test mode is relatively low.

If you have calibrated the tester using the naked substrate of this object in the "

NFe

" or "

Fe

" test mode,

set the tester in the same test mode ( in which the tester has been calibrated by using the naked substrate of

this object ). The advantage of using

"

NFe

" or "

Fe

" test modes is that measurement accuracy in "

NFe

" or

"

Fe

" test mode is high, and the disadvantage is that the tester must be calibrated in this selected test mode

beforehand by using the naked substrate of this object.

4. Firmly press the tester's probe perpendicularly against the surface of the object to be tested. When the tester

detects a stable reading, this reading will be shown on the display and it is the value of the total thickness of

the

non-magnetic coatings on the

substrate. This reading will be held on the display until the tester turns off

or you make a new measurement. If necessary, you can press the “

TEST

” button to erase this reading and

then test again.

5. If you have not operated the tester about 30 secs, it will turn off automatically. To turn off the tester manually,

hold down the "

TEST

" button for more than 1 sec.

HOW TO CALIBRATE THE TESTER

Before you make measurement in "

NFe

"or "

Fe

" mode, you must make sure that in this mode the tester has

been calibrated by using the naked substrate of the object to be tested or using a naked substrate which is

completely same as the substrate of the object to be tested.

After you finish calibrating the tester in "

NFe

" or "

Fe

" test mode, the tester will save the resulting calibration

data in this test mode automatically. The calibration data will not be lost even when the tester turns off or when

you replace the button cell. But whenever you calibrate the tester again in the same test mode, the already

existing calibration data saved in this test mode will be overwritten by the new calibration data. Thus, only the

lastest calibration data of all calibration data obtained in "

NFe

" mode can be retained in "

NFe

" mode, and

only the lastest calibration data of all calibration data obtained in "

Fe

" mode can be retained in "

Fe

" mode.

Item Specifics

Brand

all-sun

Manufacturer Part Number

allsunEM2271A

Type

Thickness Gauge

Warranty

Yes

Country/Region of Manufacture

China

UPC

788537553694

Measuring Range

0.00mm - 2.20mm, or 0.0mil - 86.0mil

Resolution

0.01mm/0.1mil

Overrange Indication

“ OL ” shown on the display

Power Supply

3V button cell, CR2032 or equivalent, 1 piece

Operating Environment

Temperature: 0ºC to 40º C

Relative Humidity

≤ 80%

Temperature Coefficient

0.15×( 2% of reading±0.05mm)/ºC (28ºC)

Storage Environment

Temperature:-10ºC to 50ºC

Size

6.9×3.8×2cm

Weight

About 29g ( including button cell )

Copyright of XXXX. All rights reserved.

Powered by SoldEazy

On Apr-22-19 at 01:39:25 PDT, seller added the following information: